INDUSTRY

CONSUMES ELEFSINA

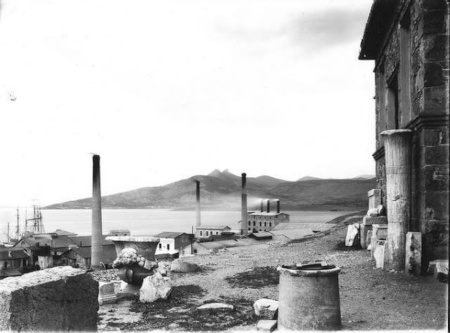

Before the smokestacks, Elefsina grew within and around the current archaeological site. The houses were built with materials taken from the decaying antiquities. The archaeological interest for the area, already manifested since the 19th century, grew simultaneously with the industrialization and urbanization of Elefsina.

The factories were built at an arm’s length from the antiquities.

The view of Elefsina’s sacred hill was eventually broadened by the smokestacks of TITAN.

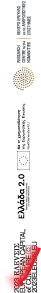

HALYVOURGIKI

In 1925, Theodoros Angelopoulos and his children Dimitris, Panagiotis and Giannis, founded the company "T. A. Angelopoulos and Sons" based in Pireos Street. Initially, the company was active in the trade of iron products and, from 1932 onwards, was renamed to "Greek Wire Mills T. A. Angelopoulos and Sons" moving on to include the manufacture of wire products, such as cables, galvanized barbed wire and nails. In 1938, the company obtained a license from the Ministry of National Economy to produce steel. However, the outbreak of World War II prohibited the production of steel by the company until 1948, when it was renamed "Halyvourgiki S.A." In 1953, the main Halyvourgiki factory was transferred to Elefsina, operating electric furnaces of 20 tons, while in 1958 a Siemens-Martin furnace weighing 40 tons was installed. In the context of the post-war reconstruction of Greece and the financial boom of the construction sector which resulted in the rise of steel demand in the late '50s, Halyvourgiki decided to integrate production vertically. Thus, in 1961, the first blast furnace for pig iron production in the country was inaugurated. Pig iron, in turn, was converted into steel by blowing oxygen into a converter. The inauguration of the blast furnace took place on the 27th July 1961 in a prominent and videotaped event attended by Prime Minister Konstantinos Karamanlis, who had invested heavily in his image as a modernizer and agent of reconstruction of the country in view of the upcoming elections, also known as elections of "violence and fraud". With the construction of a second blast furnace in the coming years, the total production capacity of Halyvourgiki amounted to over 1 million tons of pig iron per year. Apart from industrial activity, Halyvourgiki has gone down in history as the place where in 1989 about 17.5 million files documenting the "social (political) beliefs" of Greek citizens in the postwar period were burned at the stake, along with all that this action may entail for memory, oblivion, and history.

“Elaiourgiki” - Olive Oil Factory

Built in 1955, the Elaiourgiki (Olive Oil Factory) in Elefsina was in fact the first factory of the "Olive Oil Central Cooperative Union of Olive Oil Producers of Greece''. The Union was founded in 1949 and its founding members represented 90% of olive producers of the country. Elaiourgiki was built on the coastal front of the city, where the old soap factory of Hatzimeleti-Hatzielia operated from 1891-1892 until 1922. Elaiourgiki's plot was located in front of the Iris paint factory and next to the Kronos wine and spirits factory. Its premises extended over 40.8 acres of land and included warehouses and facilities constructed for processing various types of oil and the production of olives and soaps. The olive oil factory ceased its operations in 1980, when it moved to new, modern facilities in the Sarantapotamos area of Elefsina. The olive oil plant in Elefsina eventually shut down in 2013.

The Port

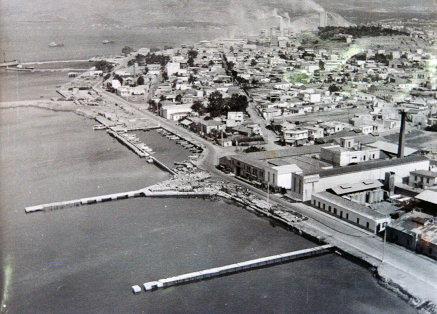

The creation of a central port was a primary intention of both the state and the industries from the period of the first industrialisation. In 1842 the Elefsina Customs Office was established, while in 1845 the Health Station was created for the medical examinations of the ships' crews. In 1914, in parallel with industrial development, the Elefsina Port Fund was established.

Specialized production, such as steel, refineries and shipyards, as well as their development after the Second World War, necessitated the expansion of the port and the construction of private docks at each factory. The Elefsina Port Fund operated until 2001, when Law 2932/200 transformed it into a joint-stock company - the Elefsina Port Authority - like all the ports in the country. Elefsina Port Authority controls the main commercial port, the former pier of the American Base and the port of Vlycha, while its assets were transferred in 2012 to the Public Private Property Development Fund.

“SKALISTIRIS BAUXITE MINES”

The Skalistiris bauxite mines derive their name from the founder of the industry complex, Dimitris Skalistiris. He was born in Athens in 1887 in a family of engineers and academics (his grandfather was the founder of the Technical University of Athens). He studied in Paris, worked in the coal mines of Northern France, and then in Germany for the AEG company. In 1924, after returning to Greece, he founded his own business and started representing large technical offices abroad. After discovering large bauxite deposits in Elefsina and Mandra, he started prospecting operations in the area in 1932. In 1936, he began exporting bauxite to Germany. During World War II, the mining facilities were destroyed and bauxite exports restarted after the conflict. In 1947, Dimitris Skalistiris acquired control of the businesses owning the large magnesium mines in Evia. In 1951, he founded Elefsina Bauxite Mines Inc. and took a loan from the US government for the mechanization and reconstruction of the mines. Its production increased to 300.000 tons of bauxite per year, out of the total annual Greek exports of 330.000 tons at the time. Dimitris Skalistiris died in 1967 and the business was taken over by his son, Michalis Skalistiris. In 1983, Skalistiris declared bankruptcy and the company was dissolved a decade later.

TITAN QUARRY

The TITAN Cement Company dug a quarry in the side of the hill, upon which medieval antiquities were located, for the extraction of raw materials necessary for the production of cement. At the TITAN quarry, workers filled the wagons with large stones and brought them to the "crusher", where they were turned into gravel.

IRIS

In 1925, the chemist Menelaos Sakellariou, a later addition to the Zurich Circle, founded the first varnish paint industry in the country under the name "Chemical Plant of Paints and Varnishes Iris L.P. – Menelaos Sakellariou and Co." The paint factory was constructed at the eastern end of the coastal front of Eleusis in an area consisting of almost 20 acres. Resin from the resin-rich forests of the Thriasian Plain was used as raw material for the Iris paint industry, a natural product utilized for many years by the resin industries of Eleusis. Iris was a pioneering industry in its field, producing during its peak oil paints, varnishes, earth paints, anti-fouling paints, floor varnishes, rosin, and printing inks. Iris applied vertically integrated production methods, i.e., maintained full control of the production chain, since it manufactured all the materials necessary for the production and packaging of its products. In the 1960s, the factory moved to Magoula and ceased its operations around 1970. Part of the building facilities as well as the central chimney holding the company's logo are preserved in the factory's initial grounds in Elefsina to this day.

"Retsinadika" - Resin Processing Plants

The resin-producing areas of Mandra and Magoula, along with easy access to the road, sea and railway network of Elefsina are the reasons behind the establishment of the resin processing plants, also known as "retsinadika", in Elefsina. Between 1890 and 1985, the resin factory of Boubousis was the first among them to begin its operations in Elefsina. It was located in the same area as the Babousis mills, on Iroon Politechniou street. The other retsinadika of Elefsina were those of Doukas and Nezis, S. Pavlos, Marneris and Pallis, Kanakis, Pantazis, Mazis, Gikas, and Stamos. The resin companies rented the forested areas in the region and placed resin collectors within them. They delivered the resin at a fixed price per ounce. The cooperatives also sold the resin by auction. Stamos' factory was in Vrachakia, Kanakis' was on the beach near Pavlos and Nezi, and Marneris' existed where a timber company and the bus station stand today.

"Each forested area was manned by 20 'retsinades', 30 'retsinades', 50 'retsinades', depending on the area; they all started, after coming to an agreement that they would work and had received good payment in advance, they got supplies of various foodstuffs and went to the mountains, to the huts that had been built in these regions, where they stayed all through summer and where usually the whole family worked (Papagiannidis, Elefsina 1986).

PYRKAL

In 1874 the "Hellenic Powder Factory SA'' of the Moraitinis brothers was founded for the manufacture of ammunition and explosives and in 1887 the company "Maltsiniotis Brothers" began operating in the same field. After many years of competition between the two companies, in 1908 the two companies merged, forming the "Hellenic Powder and Cartridge Company'' (EYCH/EPK). In 1925, a new company was founded in the Neraki area of Elefsina under the name "Hellenic Gunworks and Howitzers S.A.", a venture, however, which saw no further action, thus favoring EYCH, which held 1/3 of its shares and any activity would allow competitive action. In 1934, Prodromos Bodossakis-Athanasiadis acquired the majority of the shares of the Hellenic Powder and Cartridge Company along with the shell production machinery of Hellenic Gunworks and Howitzers S.A. that had never been used, after the company was liquidated. The production of the EYCH supplied both the Greek Ministry of Defence and the belligerents in the Spanish Civil War, as well as other states, such as China, Turkey and countries of the Middle East. In 1935, the company, at the instigation of the dictator Ioannis Metaxas, concluded a technical cooperation agreement with the company Rheinmetall, of Nazi German interests, while in 1938 a joint company of EYCH and Rheinmetall was founded based in Athens under the name "Commercial Company Reinmetall-Borshich S.A.". The CEO of the company was the Austrian Walter Deter who became manager of all Bodossaki owned companies as an officer of the Wehrmacht during the German occupation of Greece. The factory in Eleusis was requisitioned by the Germans and operated according to the needs of the Wehrmacht. After the withdrawal of the Germans, the company, which had suffered many damages both during the German occupation and the Greek Civil War, went through a period of great recession and moved on to the production of products for peaceful use (meat grinders, spoons, lighters, hinges, tools, etc.). Gradually, the company recovered thanks to production orders from the Greek army and NATO. The production activity at the facilities of Elefsina extended to two factories, the Pyrotechnic Factory, where primary explosives were produced, and another one, where the charges and assemblies of cartridges, mortars, projectiles and missiles of various calibers was carried out, as well as the discharge/deactivation of ammunition. In 1983, after large mobilizations by the workers' unions, PYRKAL was affected by PASOK's law on "socialization", i.e., nationalization of companies, while in 2004 it merged with the Hellenic Arms Industry (E.B.O.), its main competitor until then, forming the group of EAS companies (Hellenic Defense Systems). In 2017, the PYRKAL plant in Elefsina became property of Hellenic Petroleum and in 2019 it was declared a historical site, with 12 of its 134 buildings listed as monuments.

PETROLA – ELPE

In 1969, the Latsis Group, owned by shipowner John Latsis, founded PETROLA-HELLAS S.A. and in 1972 inaugurated the PETROLA refinery in Elefsina in an area of approximately 1.800 acres on the coast of Vlycha, west of the city. In order to install the refinery, the holiday settlement of Elefsinia (2000 acres of land and 900 acres of sea) was expropriated, raising many reactions and protests by the locals. The new PETROLA refinery had 84 oil storage tanks, with a total volume of 3.600 cubic meters. The waste of the oil industry polluted both the air and the sea significantly, which came to aggravate the existing and escalating pollution of the region of Western Attica. Although the settlement permit was initially temporary, it was legalized in 1975, while in 1979 permission was given for an extension, which, however, was canceled due to the organized collective reactions and protests of the residents. On September 1st 1992, the deadliest work accident in Elefsina took place at the PETROLA plant, when a fire broke out due to a leak of a flammable substance (naphtha), resulting in 15 deaths and 10 injuries. In 2003, the facilities of PETROLA became property of ELPE (Hellenic Petroleum).

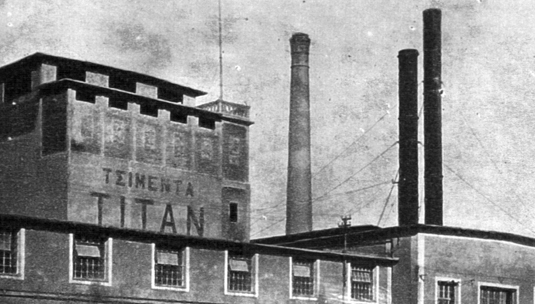

TITAN CEMENT INDUSTRY

In 1902, members of the Zurich Circle, chemists Nikolaos Kanellopoulos, Leontios Economides, Andreas Hadjikyriakos, and the civil engineer Alexandros Zachariou founded the Limited Partnership "Hadjikyriakou-Zachariou & Co.", based in Piraeus. They immediately began the installation of the first Greek cement plant in the Gulf of Elefsina. In 1911, it acquired the name by which it is known to this day and in 1912, while Nikolaos Kanellopoulos was president, its share was listed in the Athens Stock Exchange. The raw materials were baked in vertical Schneider-type furnaces and fed from the top with briquettes containing the raw material along with coal powder, producing 35 tons per day. In the 1930s, the so-called "TITAN Houses" were constructed in the western part of the plant, i.e., social housing for employees. These houses, which are now demolished, remained in use for several decades. In 1936, TITAN workers participated for 52 days in a major strike in the region, achieving many of their demands, such as higher wages. In the same year, TITAN cement was used in the construction of the Roupel fortifications, based on a special patent purchased from Switzerland. During the German occupation, the factory continued to operate partially. In 1949, TITAN joined the Marshall Plan loan, dramatically increasing its production over the next few years due to the country's growing needs for postwar reconstruction. In 1961, electrostatic filters were installed in an effort to protect the environment and the health of the workers, which had been significantly affected in previous years by the production of the factory. In 1976, the TITAN plant in Kamari, Viotia, was inaugurated and, gradually, all cement production was transferred there, with the facilities in Elefsina now constituting the company's logistical center.

VOTRYS

In 1898, the members of the Zurich Circle Epaminondas Charilaos and Leontios Economides founded the "Charilaos & Co. Winery and Distillery Company''. Within the next year, the construction of the plant in Elefsina began on a plot of land that surrounds the western and northern parts of the plot of the Elaiourgio (Olive Oil Mill), while also bordering the cement industry TITAN and the archaeological site. Since 1906, after the merger of the company with another winery of Charilaos, the "Anonymous Greek Company of Wines and Spirits-Votrys'' was founded, more widely known as "Votrys". In the following years, it became a dominant industry in its field. It used raisins and its byproducts as raw material, especially when the country was plagued by the Raisin Crisis, i.e., when large quantities of raisins remained unsold due to overproduction and led to a subsequent fall in demand, eventually leading the agricultural sector towards economic recession. Starting from raisins, the Votrys factory produced wine, brandy, vermouth, spirits, as well as light alcohol, which competed with petroleum products, and raisins’ extract, which acted as a substitute for sugar at a time when the latter was in great shortage. Votrys' products were sold domestically and exported abroad. In 1938, after a period of crisis following the Asia Minor Catastrophe, the Votrys factory became property of Prodromos Bodossakis-Athanasiadis. During the German occupation of Greece, the factory was requisitioned by the Nazis. In 1973, Bodossakis founded the Bodossaki Foundation to which he transferred all his property, including Votrys. Αfter his death, in 1979, the factory passed into the hands of his nephew Alexandros Athanasiadis, before closing permanently in 1986.

SOAP FACTORY – OLIVE OIL MILL

The first industrial unit of Elefsina was the Charilaou Soap Factory founded in 1875 by brothers Lysandros and Emmanuel Charilaos, originally from Galați, Romania. The factory was constructed at the western end of the city, between the coast and the hill of the archaeological site. Initially, it was a small-scale unit which operated with 20 workers, a 30 horsepower steam engine, and olive kernels as raw material. Twenty years later, in 1895, Epaminondas Charilaos, nephew of the founders, together with Nikolaos Kanelopoulos, both chemists belonging to the Zurich Circle, took over the management of the Soap Factory and transformed it into the well-known Elaiourgio (Olive Oil Mill) under the name "Charilaos-Canellopoulos S.A.". The industrial unit grew to 90 workers in 1900 and 250 in 1928. The prewar production of the Soap Factory-Elaiourgio included pomace oils, linseed oils, cotton oils, castor oils, coconut oils, refined seed oils, glycerin, green soaps and the "Soaps of Elefsina", i.e., white soaps of the Marseille type. Production was increasing, and, apart from the domestic market, it also included exports to other Mediterranean countries. The Elaiourgio ceased its operations at the end of the 1960s and from 2007 onwards its grounds were given to the municipality of Elefsina by the National Bank of Greece for the organization of the art festival of Aeschylia.

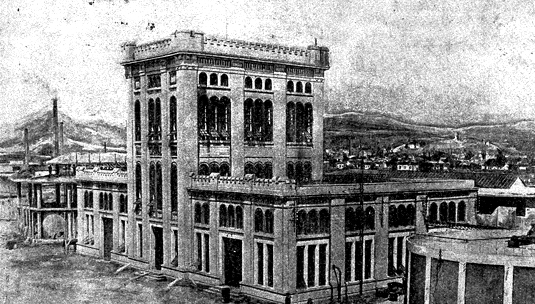

KRONOS

The Distillery Societe Anonyme was founded in 1911 in Piraeus and between 1923 and 1926 the company's factory known as "Kronos" was built in the eastern end of the coastal front of Elefsina. Until the construction of Halyvourgiki in the 1960s, Kronos marked the farthest end of the city's coastal industrial zone to the east. As raw materials, Kronos used grapes, while utilizing steam and oil as energy sources. It produced wine, alcohol products, molasses and tanning extracts for tanning. In the first years of its operation, Kronos employed about 300 people. In the great strike of 1929, in which Kronos' workers participated, the gendarmerie opened fire at the strikers, resulting in 1 dead and 8 wounded. Besides industrial activity, the very building of Kronos, an example of interwar architecture of a rapidly changing society, remains a landmark of the region to this today. Pavlos Santorinis, physicist, professor at the National Technical University of Athens, and a later addition to the Zurich Circle, introduced static innovations to the construction of the factory through the introduction of reinforced concrete. The project was undertaken by the company of civil engineer Alexandros Zachariou, another member of the Zurich Circle, "Tekton S.A.". The emblematic neo-Gothic architecture with the use of reinforced concrete, an innovative material for its time, stands out particularly in the tower-like complex of the distillery, revealing the mingling between the trends of the late 19th and early 20th centuries. The Kronos factory operated until 1986, was bought in 1991 by a private individual, and served for many years as a storage space and a place to host art exhibitions and cultural events such as the Aeschylia Festival. In 2023, the historic building of Kronos became property of the municipality of Eleusis.

ELEFSINA SHIPYARDS

The Elefsina shipyards were founded in 1962 by shipowner, banker, and professor of administrative law Stratis Andreadis. For their installation, the location "Elefsinia" on the Gulf of Elefsis was chosen, where approximately 150.000 square meters of rocky area were leveled, eventually occupying 1.100 meters of the coastal front. They inaugurated their operations in August 1969, in the presence of the dictator George Papadopoulos, by launching a repair base for ships and boats of all categories. Their proximity to steel industries, which supplied materials necessary for shipbuilding and repairs, the electricity and telecommunications infrastructure of the area, which was already an important industrial zone, and the relocation of the railway line and the motorway to serve the company, led to the expansion and dominance of the Elefsina shipyards in the following years, which maintained a staff of 300 people in 1975. On April 6 1972, Maundy Thursday, one of the most traumatic accidents in the collective memory of Elefsina took place at the shipyards, when the collapse of a metal crane bridge 60 meters high and weighing 300 tons, built by the German company Krupp, caused the death of 9 workers (7 Greek and 2 German). During the transition to democracy, the Elefsina shipyards became property of the Greek state and were privatized again in 1992.

Although industrial activity in Elefsina began during the late 19th century, it was the construction of the TITAN industry in 1902, with its smokestacks and quarry, that defined it as an industrial city. The TITAN facilities bordered on both the coast and the antiquities, interrupting thus the continuity between the coastal front and the city in the west. The quarry "swallowed" the mountain overlooking the beach, leaving behind four small rocks and plenty of memories for those who used to cross its threshold in order to reach the sea.

We would go to the rocks, sometimes with my mom, but it was a lot of walking and there was no bus, so we had to go up and down the mountain… TITAN was cutting the mountain down, blasting it, breaking it into cement, and we eventually saw that the mountain was running out of rocks, the mountain had gotten smaller, only a tip was left, none of it eventually remained.

SPIRIDOULA GKINI

IT TURNED

THE MOUNTAIN

INTO CEMENT

A township of Symiots was established at Vrachakia, where we stayed until 1966, when it was expropriated by TITAN. It got so close to the quarry and the blasting sites that, when they were about to detonate the explosives, they would shout "varda fournelo!" [fire in the hole!] and we would hide inside the house, rocks would fall on the roof; they were raining down on us…

THODOROS KOUNELES

TITAN also "swallowed" the antiquities buried within the mountain.

It was a time when the parallel lives of industrialization and the promotion of Elefsina’s archaeological heritage could allow for such sacrifices.

TITAN’s cement assisted in the reconstruction of the city as well as that of the country.

THEY THREW

THE RELICS

IN THE

CRUSHER

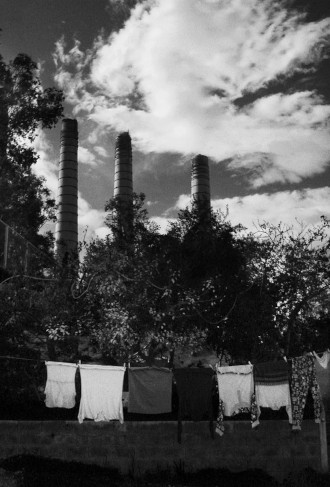

TITAN’s smokestacks covered the city with clouds of cement dust, which, in time, enveloped the roofs of the houses, soiled the clothes hanging on clotheslines, but also provided jobs and income to the households of Elefsina at the same time.

At the small church of Saint Nikolaos that stands between the smokestacks, the soil of the courtyard is barely visible through cracks in the layer of cement dust which has accumulated on the spot over the years.

I mean, you could see the area becoming white. Dust, on the other hand, because of the many years of operation, had settled on the walls, I mean, everywhere. And whenever there were strong winds, you could see a dust cloud rise.

ANTONIS ZAMPELIS

The cement raining down was a problem for the women doing their laundry while cement rained from above, and they had to rewash their clothes, so they went to TITAN and were given ROL (a detergent brand) and soap.

EVANGELIA NODARA

Various smaller or larger plants, such as the Kronos distillery and the Iris paint and varnish factory,

gradually occupied the coastal front during the second period of Elefsina’s industrialization.

Up until the 1920s, raw materials and goods were being loaded and unloaded through small temporary piers constructed and owned by the various industries.

The coordinated development of the port began after the establishment of the large industries to the east of the Elefsina.

The port of Elefsina, at the time public property, amassed the imported raw materials, while the private ports of factories such as TITAN and Votrys served as facilities for the export of the industry's end products.

During the interwar period, the industrial landscape of Elefsina expanded through the construction of the factory of HALYPS, while the industry that would later be known as PYRKAL was installed in the west, adjacent to the mountain hollowed out by TITAN.

The third period (1948-1971) was marked by the installations of Chalyvourgiki, Elaiourgiki, the shipyards, and the refinery plant of PETROLA, which bordered with PYRKAL.

The urban landscape was marked by the additions of blast furnaces, tanks, and smokestacks, tainting the coast, air, and sea.

I mean, imagine that in the entire area of Elefsina there are two types of smog, one is pink and comes from Halyvourgiki, and the other is white, cement-white, and comes from TITAN. Sometimes the first would get you, other times the second would. And, of course, there are also the songs written by Chatzidakis and all that.

IRAKLIS MPEKAS

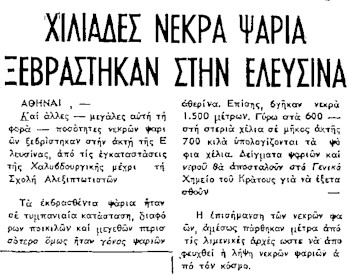

FISH

COVERED

THE SURFACE,

FLOATING

ON THE SEA

At the pinnacle of its industrialization, Elefsina lost the littoral aspects of its character. The new industries required transportation of materials and goods in large volumes, and intensive use of the seafront, along with supporting services, resulting in the development of the ship-breaking yards in Vlycha, to the west of the region.

Vrachakia, Vlycha, and Elefsinia used to be beachfronts and famous summer vacationing spots, known for their shellfish, fish, and boat rides. Nowadays, the sight of decommissioned ships, embankments, shipyards, the facilities of ELPE and the unofficial graveyard of ship evokes nothing of the old Attican landscape.